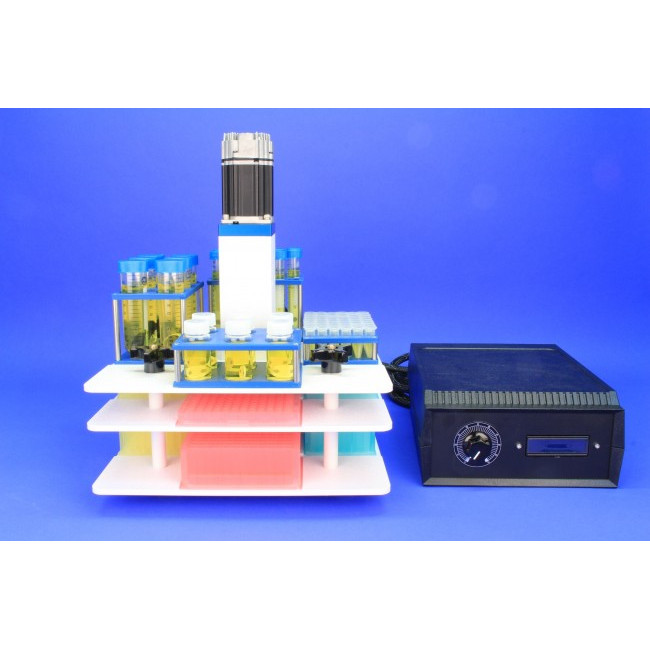

Rotary Magnetic Tumble Stirrer, Servo Motor powered for high speed and high torque, low profile 16.5 cm long usable stirring deck, with plate holder, stirs 2 deep well microplates or 8 standard microplates (stacked), space for gripper access between plates, RPM readout on control unit LCD, 115/230 Volts, 60/50 Hz, CE compliantPatent #6,176,6097 and 7,484,880

Vortex Lateral Tumble Stirrers

We found by simply standing a Vertical Tumble Stirrer on end using a VP 710C5-3 or VP 710C5-3A we created the world’s first LATERAL VORTEX MICROPLATE TUMBLE STIRRER (USA Patent #7,484,880, European Union Patent #1,736,235 and German Patent #60 2006 026 122.5). Instead of tumbling a stir element in the vertical plane like our Alligator Tumble Stirrer, the Lateral Vortex Tumble Stirrer spins the stir elements by tumbling them laterally against a side wall of the vessel. This spinning motion produces a vortex cone in the liquid and efficiently mixes the contents of the liquid. This vortex cone is similar to the vortex cones produced by conventional horizontal magnetic stirrers however unlike the conventional horizontal stirrers which require a unique drive magnetic field under each vessel, the Vortex Stirrer because of its lateral wall tumbling action only requires one drive magnetic field to stir thousands of vessels. The Vortex Tumble Stirrers work best with round micro wells, or round tubes, vials and bottles. Basically our customers can convert our VP 710 series Tumble Stirrers into Lateral Vortex Stirrers by standing them on end with our accessory stands (VP 710C5-3 or VP 710C5-3A) which hold the stirrer vertical.

The Lateral Vortex Tumble Stirrer causes stir elements of all sizes and shapes to tumble laterally and create a vortex cone inside each well. The Lateral Vortex Tumble Stirrer will stir all types of microplates (24, 48, 96, 384 and even 1536 wells). It will also stir V and U bottom microplates, PCR plates, micro-centrifuge tubes, test tubes, vials and bottles. The only Stir elements that are not compatible with the Lateral Vortex Tumble Stirrer are the Stainless Steel Discs as the magnetic field in these stir elements is oriented through the diameter of the disc. These discs will simply spin in the wells causing little stirring action.

Advantages of the System

• Can stir multiple, vials, tubes, large vessels and microplates simultaneously

• Complete stirring of large numbers of samples

• Uniformity of stirring of wells throughout the microplate

• Can run multiple experiments in parallel

• Get more reactions per gram of starting material

• Will stir even viscous solutions (honey & glycerol)

• No cross contamination – wells do not have to be sealed

• Simple to operate

• Customizable to robotic systems

• Can stir continuously for years without maintenance

• Computer control option is available

Alligator Vertical Tumble Stirrers

The Alligator Magnetic Vertical Tumble Stirrer uses patented stir-cylinder technology to mix large numbers of samples in tubes, vials, bottles, and microplates (USA Patent #6,176,609). Instead of spinning a magnetic stir bar about the horizontal plane like the standard magnetic flask stirrer, the Alligator Vertical Tumble Stirrer causes stir elements of all sizes and shapes to tumble vertically end-over-end inside each well or vessel. The Alligator Vertical Tumble Stirrer will stir all types of microplates of any volume or format. It will also stir V and U bottom microplates, PCR plates, micro-centrifuge tubes, test tubes, syringes, vials and bottles, and special designed troughs and reservoirs. Perhaps the best way to appreciate how the Allligator Vertical Tumble Stirrers function is to see all the videos above this section.

Advantages of the Vertical Tumble Stirring System

Many Models available

Using the most powerful permanent magnets manufactured, we make many different models of Vertical Tumble Stirrers to fit the many varied applications and requirements of our customers. Requirements for heating and continuous stirring for a long period of time demands special Vertical Tumble Stirrers that are resistant to heat and with motors capable of working under high loads for extended periods. We make our Vertical Tumble Stirrers heat resistant using Mica. The Mica deck will accommodate three of our V&P heat blocks operating at 200C. Please check with our knowledgeable staff to help you make the appropriate selection for your application. Our specialty is flexibility- let us know if you have a custom application today!

Published Articles

Click here for a list of published articles that cite using the products on this page.

Stir Elements designed for Vertical Tumble Stirring

We offer a large assortment of economical magnetic Stainless Steel Stir Elements from Stir StiXs to Discs to bars and dowels to fit into any well, vial, tube or syringe. Check out the Stir Element page for more information on coatings and dimensions.

We also sell Alnico and Rare Earth Magnetic Stir Bars for more viscous solutions.

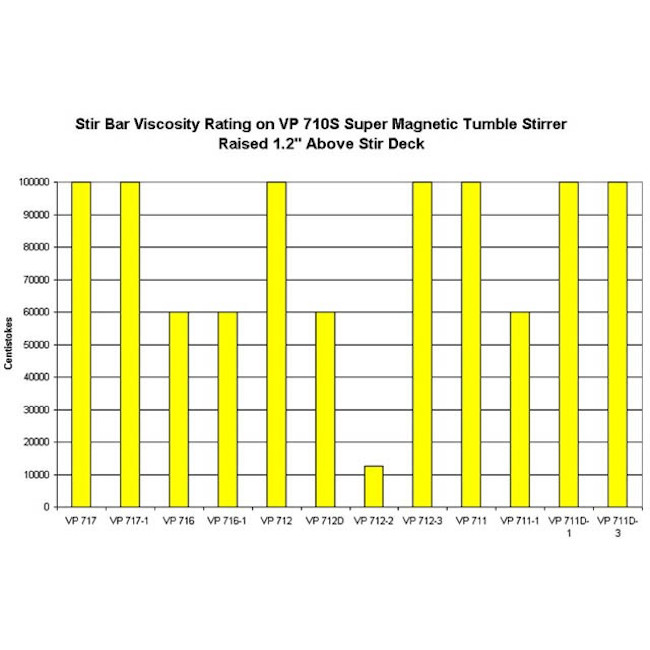

Tumble Stirring Viscous Solutions

The ability to stir extremely viscous solutions, slurries and emulsions is a very useful characteristic of the V&P Alligator Tumble Stirrers. Our Vertical Tumble Stirrers and Stir Elements have the ability to mix even solutions of 100,000 centistokes (6.6 times more viscous than honey).

Stir Element Data

V&P Scientific's Unique and Patented Vertical Tumble Stirring Systems Applications

Rapid and efficient stirring of any format microplates, test tubes, vials and syringes See Video

Thorough mixing of 2 or more liquid solutions

Thorough mixing of slurries, viscous solutions and emulsions

Thorough mixing of immiscible liquids (Stir StiX)

Keep particulates in suspension (Insert Link to Bubble Paddles)

Resuspend chemical libraries after storage

Aeration of microbial cultures to increase DNA or protein yield

Miniaturization of fermentations & chemical reactions

Stirring chemical reactions to speed completion

Heat and Stir to facilitate compound synthesis

Enables parallel synthetic development of processes

Resuspend settled microorganisms

Keep microorganisms suspended during gridding operations

Break up filamentous organisms

Dissolve solid compounds

Resoluabilize dried extracts from large screening libraries

Mix and immobilize reactions that use magnetic beads

Computer control for use on automated liquid handling platforms (LINK to VP 710CC)

VP 710-CC software

Gifs

Plot of the magnetic field strength versus distance from the Alligator Magnetic Tumble Stirrer deck.

The magnetic field strength (lines of flux per square inch) are as follows:

On the surface of a 42 Mega Gauss Oersteds (42 MGO) rated magnet, the magnetic field strength is 13,000 gauss.* This strength falls off quickly as the distance increases. We try to position the magnet as close to the deck as possible given the constraints of the magnetic cylinders and deck design. The VP 710F D4 and D6 deck design places the magnetic cylinder closer to the deck than the even more powerful VP 710S so it appears to be stronger at the deck surface. However, it is not able to project this field as far as the VP 710S.

The MGO rating for the magnets used in the following tumble stirrers are listed as superscripts after the product numbers

(42, 45, or 48 )

| Gauss Units At Defined Distances From The Cylinder Guard Of A Vortex Lateral Tumble Stirrer | ||||||

| Inches from the cylinder guard0 | VP 708A (42MGO) | VP 708A (42MGO) | VP 708A (42MGO) | |||

| Top (Platter 1) | Middle (Platter 4) | Bottom (Platter 6) | ||||

| 0 | 957 | 1138 | 1022 | |||

| 6 | 23.7 | 28.1 | 23.2 | |||

| 12 | 5.2 | 5.4 | 4.8 | |||

| 18 | 2.0 | 2.1 | 1.8 | |||

| 24 | 0.7 | 1.2 | 1.0 | |||

| 30 | 0 | 0.8 | 0.5 | |||

| 36 | 0 | 0 | 0 | |||

| Distance Away From Cylinder Guard For 5 Gauss Units | ||||||

| 5 Gauss (in inches) | 12.5" | 13" | ||||