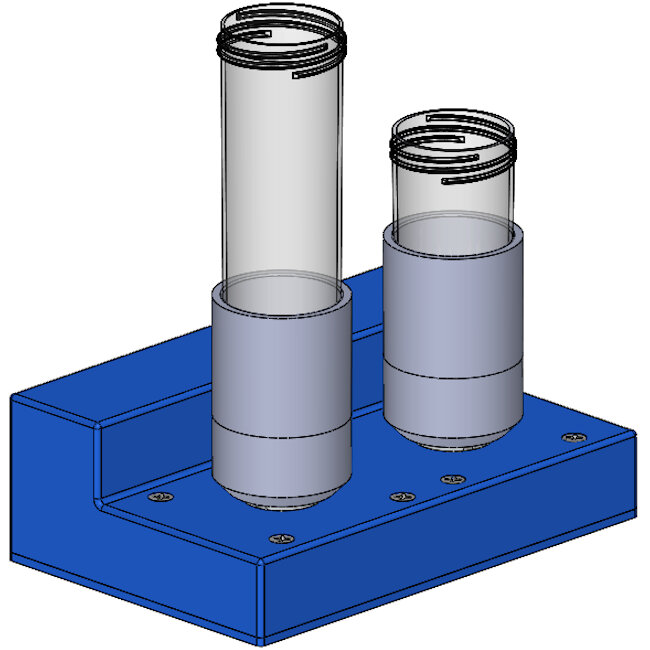

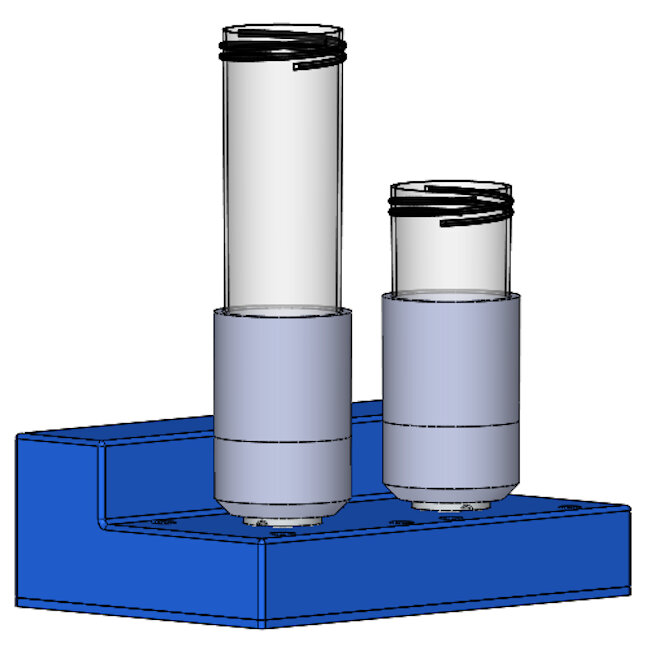

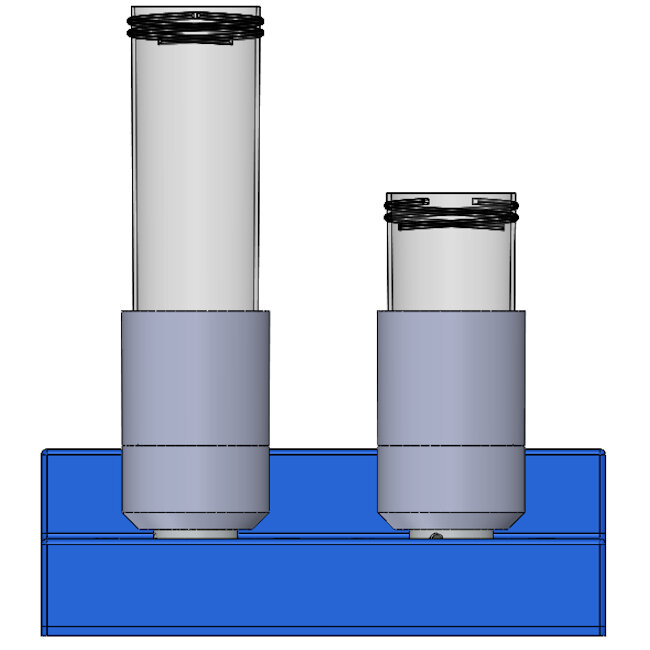

SpinVessel® System for two - 50 ml conical bottom SpinVessels®, direct drive stepper motor, aluminum enclosure, digital touch screen controller, 100-240 Volts, 50-60 Hz, CE compliant

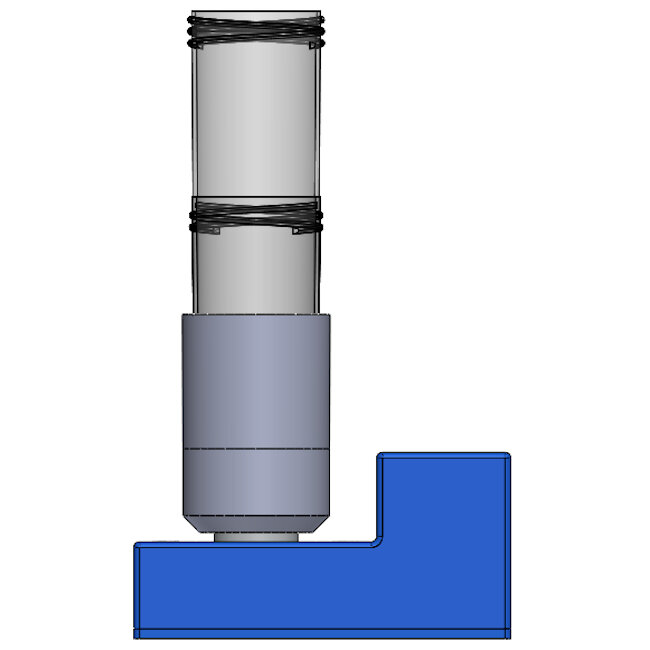

Our unique method of mixing and suspending particulates is predicated on fluid dynamics and flow geometry. Our method of mixing is achieved by integrating radially oriented side fins and projections in a vessel and connecting the vessel to a machine that alternately reverses the vessel’s spin direction to generate a circular pulsed radial fluid flow. The flow path starts at the bottom of the vessel, where the fluid and particulates are pushed to the side walls of the vessel. As the fluid and particle mixture strikes the side wall, the side fins guide the fluid flow up the vessel, thus generating lift along the vessel walls. The fluid flow loop is completed by the mixture flowing down the center of the vessel due to gravity and the nature of radial flow.