Parylene Coating of Tumble Stir Elements

V&P Scientific also offers inexpensive stainless steel stir elements that are coated with parylene, for those applications facilitated by mixing (combinatorial chemistry and redox synthesis) where Fe molecules may interfere with the reaction, or the stirrers would be attacked by strong acids or bases. The low cost of these parylene coated stir elements allows them to be considered "disposable". Parylene (Di-Para-Xylylene) is deposited on the surface of the stirrer in a very uniform 0.05 mm thick layer, thus protecting the stirrers from strong acids and bases. Parylene coated stirrers can be autoclaved or sterilized in hot air ovens without harming the conformal coating. Parylene can be heated to 200°C without harming the surface.

Parylene is also compatible with biological applications. In fact, parylene is used to coat materials for implant procedures, as it is completely non-toxic to tissues. A very complete discussion of parylene's barrier characteristics, properties and methods of deposition is found at this hyperlink. Another page is dedicated to parylene’ s resistance to organic solvents, acids and bases.

.

Many of the applications using parylene coated stainless steel stir element fall into the categories of parallel synthesis, combinatorial chemistry and redox synthesis that are done by pharmaceutical companies and most are never published in order to keep their data and methods private. One of our customers at a large pharmaceutical company sent us this complement in an email -

"Patty and Patrick-

There is a long, official process (read: involves Legal department) for allowing endorsements of products with _______'s and/or my name. However, I would be happy to share my personal feedback to you. If you would like to refer this to anyone as unofficial information (ie, "It came from someone in Process R&D in major Pharma."), that would be great. At the least, you'll see exactly why I love these stirrers.

Feedback for the Tumble Stirrers is this: enabling technology. I am now enabled to create reaction blocks and customize them to robotic systems with great ease. Why? The narrow deck height of the Tumble stirrers (even my larger strength units) combined with flexibility of alignment for the stirrers to the reaction vessels means I can use them almost anywhere.

The fact that I can use the same stirrer deck with any type/size of reactor simply by changing a mounting plate atop the stirrer deck gives me the kind of flexibility I require for parallel synthetic development of processes. That flexibility enables access to a wider range of projects (smaller scale) and a wider range of reaction conditions. I get more reactions per gram of starting material for evaluation of more diverse conditions, and I generate results faster because I run more of the experiments in parallel using the same amount of starting material. In one word, Tumble Stirring is enabling.

Oh, and the quality of agitation is fantastic for liquid-liquid mixes, slurries, or even oil suspensions.

Thanks again for this terrific product.

D____."

A partial list of articles referencing our products and organized by application can be found on this page.

Click here for a list of published articles that cite parylene coating of various articles.

The Parylene Coated Tumble Stirrers can be dispensed with the same dispensers as their non-coated counterparts.

V&P Stir Balls were designed to mix and stir the contents of deep well microplates and to facilitate chemical or biological reactions. These stir balls work best when used with the strong magnetic fields generated by our Levitation Stirrers.

Our Levitation Stirrers were invented by us and first used by Celera Genomics to mix the contents of 384 deep well microplates and resuspend human DNA from bacterial cultures so it could be sequenced. At the time, Celera Genomics said our Levitation Stirrers were an “enabling technology” that allowed them to competely sequence 5 different humans while the US government and and all the other countries and companies that worked on the Human Genome Project collaborated to sequence just one human.

- V&P Scientific's Unique and Patented Levitation Stirring Applications

- Resuspension of DNA in deep well microplates

- Assays to determine optimal biocide concentration in viscous solutions like lotions, toothpaste, mascara, paint, etc.

- Rapid and efficient stirring of 96 and 384 deep well microplates

- Thorough mixing of 2 or more viscous solutions

- Mix emulsions

- Keeps particulates in suspension

- Aeration of microbial cultures to increase DNA or protein yield

- Miniaturization of fermentations

Magnetic Levitation Stirrers

The V&P Scientific, Inc. Magnetic Levitation Stirrers (US patent #6,357,907; EU patent #1064988) were designed to stir the tall narrow columns of deep well 96 and Whatman Polyfiltronics deep well 384 microplates. As scientists have sought to increase throughput of many processes they have turned to miniaturization and deep well microplates as a solution. However one of the problems of using deep well microplates is being able to adequately mix the well contents or to resuspend particles in these tall narrow wells. Another problem was that of getting enough oxygen exchange through the relatively small surface area of the deep well. We invented Magnetic Levitation Stirring as an efficient and inexpensive method to aerate and mix the contents of deep well microplates. We have done this by simply raising and lowering stainless steel balls in all the wells by using a very strong horizontal magnetic field. This method produces a very vigorous stirring action which stimulates growth of microorganisms, mixes with ease two or more liquids, and keeps particulates in suspension. Furthermore, if the media level in the wells is adjusted so the stir balls pass through the meniscus, aeration of a microbial culture is increased and results in greater microbial yield as well as DNA and protein production.

The ability to stir extremely viscous solutions is a very useful characteristic of all the V&P Levitation Stirrers. Our Levitation Stirrers and Stir Balls are able to mix even solutions of 100,000 centistokes or 6.6 times more viscous than honey. A series of silicone viscosity standards was placed in the columns of a deep well microplate. The standard series viscosity was as follows: 100 cst, 1,000 cst, 5,000 cst, 10,000 cst, 12,500 cst, 30,000 cst, 60,000 cst and 100,000 cst.

For comparison 1 centistoke = 1.0760 x 10E-5 sq. ft./sec.,

water = 1 cst

molasses ~ 2,500 cst

honey ~ 15,000 cst

Our VP 707B and VP 707C series Levitation stirrers can mix viscous solutions up to 30,000 cst while our VP 707E series Levitation stirrers are able to mix viscous solutions up to 100,000 cst because these stirrers use the magnet to also pull the stir balls down as well as to levitate them up. The VP 707B and VP 707C series Levitation Stirrers rely on gravity to pull the stir balls down.

Advantages of the System

- Thorough stirring of large numbers of samples

- Thorough stirring in tall narrow wells

- Will stir even viscous solutions

(100,000 centistokes)

- No cross contamination – wells do not have to be sealed

- Simple to operate

Accessories

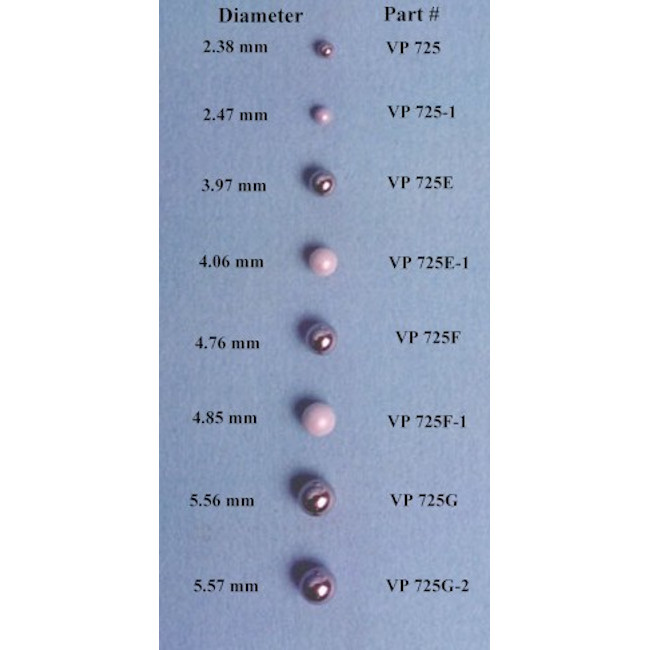

The Levitation Stir Balls are made from corrosion resistant stainless steel and come in a variety of sizes to accommodate all 96 and 384 deep well microplates. The Levitation Stir Balls are also provided encapsulated in parylene for combinatorial chemical reactions and other reactions that may be sensitive to metal ions. Also, Sterile Levitation Stir Balls are provided. Although the cost of the balls is low enough to discard them after one use, they can be recovered, washed, demagnetized and used over and over. Each of the Levitation Stir Balls is tested for magnetic energy and only those that pass our stringent testing are accepted.

Dispensers for loading the balls into the wells are also available for each size of ball. These dispensers can quickly and accurately place sterile or non-sterile balls into the wells. One of the advantages of stainless steel balls over permanent magnets is that the stainless steel may be demagnetized so they don't "clump" in the dispensers as the permanent magnets do.

Removing the balls from the wells after they are used can be done as easily and as sterilely as your assay conditions dictate. If your assay is completed and all the liquid has been removed you can simply invert the microplate and magnetically collect the balls as they fall out. If the liquid is still in the wells and you want to remove the balls and leave the liquid behind just use the VP 770 Magnetic Plate System for stir ball extraction and the VP 384AM Magnetic Long Pin Replicator. A third way to remove the balls is with our VP 772 Magnetic Unloading System which uses a very strong magnet to remove the balls quickly and efficiently.

Scientists can apply this unique methodology to many different areas that require mixing of liquids or suspending particulates in the tall narrow wells of deep well microplates. The most cost effective is the manual Magnetic Levitation Stirrer VP 707. With as few as 10 back and forth strokes the contents of the wells are mixed. This Stirrer functions to levitate the balls by sliding the microplate through a horizontal magnetic field and then pulls the balls down by passing over a vertical magnetic field. The VP 707 is ideally suited to stir combinatorial chemical reactions or other reactions where continuous stirring is not required. The manual VP 707 has a footprint of only 20 cm wide by 64 cm long and 16 cm tall. This stirrer will stir one deep well microplate at a time at up to 100 lifts/minute.

All Levitation Stirrers are equipped with microplate "hold down shoes" designed to fit the Polyfiltronic/Whatman 384 deep well blocks (Uni Plate 400 - 400 ul volume) and ABgene's 96 deep well blocks (2.2 ml volume) #AB-0661. Both these deep well blocks have a broad flat flange on the bottom and no skirt. This feature allows us to easily capture the plate and hold it securely in the strong magnetic field. Hold down shoes for other manufacture's microplates will be done on a custom basis.

We also have microplate "hold down shoes" for Seahorse BioScience's 4 ml 96 well blocks to fit on the VP 707C Linear Levitation Shuttle. We have also made custom "hold down shoes" for Seahorse's 4 ml 96 well blocks that fit on the VP 707B Carousel.

Gifs