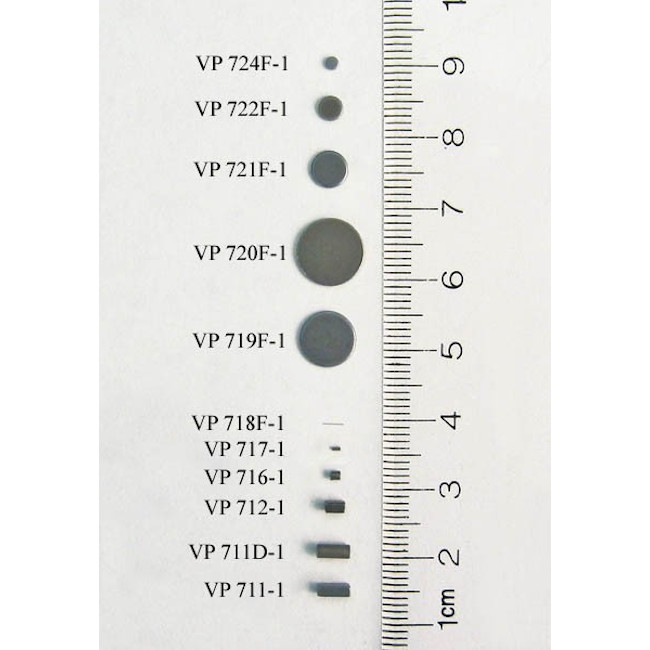

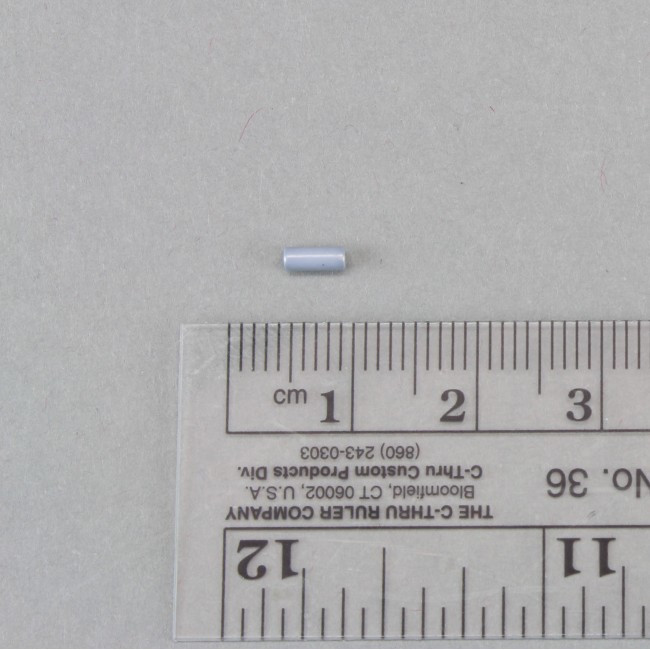

Parylene coated VP 711D Super Tumble Stir Dowels - 1.98mm diameter, 4.80mm length, 200 C maximum operating temperature, 1000/pkg

Parylene Coating of Tumble Stir Elements

V&P Scientific also offers inexpensive stainless steel stir elements that are coated with parylene, for those applications facilitated by mixing (combinatorial chemistry and redox synthesis) where Fe molecules may interfere with the reaction, or the stirrers would be attacked by strong acids or bases. The low cost of these parylene coated stir elements allows them to be considered "disposable". Parylene (Di-Para-Xylylene) is deposited on the surface of the stirrer in a very uniform 0.05 mm thick layer, thus protecting the stirrers from strong acids and bases. Parylene coated stirrers can be autoclaved or sterilized in hot air ovens without harming the conformal coating. Parylene can be heated to 200°C without harming the surface.

Parylene is also compatible with biological applications. In fact, parylene is used to coat materials for implant procedures, as it is completely non-toxic to tissues. A very complete discussion of parylene's barrier characteristics, properties and methods of deposition is found at this hyperlink. Another page is dedicated to parylene’ s resistance to organic solvents, acids and bases.

.

Many of the applications using parylene coated stainless steel stir element fall into the categories of parallel synthesis, combinatorial chemistry and redox synthesis that are done by pharmaceutical companies and most are never published in order to keep their data and methods private. One of our customers at a large pharmaceutical company sent us this complement in an email -

"Patty and Patrick-

There is a long, official process (read: involves Legal department) for allowing endorsements of products with _______'s and/or my name. However, I would be happy to share my personal feedback to you. If you would like to refer this to anyone as unofficial information (ie, "It came from someone in Process R&D in major Pharma."), that would be great. At the least, you'll see exactly why I love these stirrers.

Feedback for the Tumble Stirrers is this: enabling technology. I am now enabled to create reaction blocks and customize them to robotic systems with great ease. Why? The narrow deck height of the Tumble stirrers (even my larger strength units) combined with flexibility of alignment for the stirrers to the reaction vessels means I can use them almost anywhere.

The fact that I can use the same stirrer deck with any type/size of reactor simply by changing a mounting plate atop the stirrer deck gives me the kind of flexibility I require for parallel synthetic development of processes. That flexibility enables access to a wider range of projects (smaller scale) and a wider range of reaction conditions. I get more reactions per gram of starting material for evaluation of more diverse conditions, and I generate results faster because I run more of the experiments in parallel using the same amount of starting material. In one word, Tumble Stirring is enabling.

Oh, and the quality of agitation is fantastic for liquid-liquid mixes, slurries, or even oil suspensions.

Thanks again for this terrific product.

D____."

A partial list of articles referencing our products and organized by application can be found on this page.

Click here for a list of published articles that cite parylene coating of various articles.

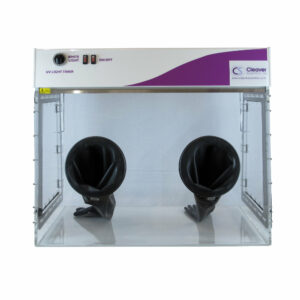

The Parylene Coated Tumble Stirrers can be dispensed with the same dispensers as their non-coated counterparts.

V&P Stir elements were designed to mix and stir the contents of microplate wells and to facilitate chemical or biological reactions. These stir elements work best when used with the strong magnetic fields generated by our Vertical Tumble Stirrers or with our Lateral Vortex Stirrers using NdFeB magnetic cylinders. The strength of these magnetic fields is so strong that they will even cause inexpensive weakly magnetic stainless steel stir elements to tumble when they are even 12.8 cm above the stirrer's deck. Furthermore the cost of the stainless steel stir elements is so low as to be considered "disposable".

High Throughput Stirring Platform

The NdFeB magnetic cylinders used with both our Vertical and Lateral Tumble Stirrers are constructed to project a very strong magnetic field for 60 cm. When used with our Vertical Tumble Stirrers, microplates can be stirred when stacked 8 microplates high (12.8cm) with stainless steel stir elements and stirred up to 19 microplates high (30.4 cm) when used with NdFeB stir elements. This great projection of magnetic field strength allows for experiments of up to 40 microplates using stainless steel stir elements and 95 microplates when using NdFeB stir elements on a VP 710E5.

V&P Scientific's Unique and Patented Vertical Tumble Stirring Systems Applications

Vortex Lateral Tumble Stirrers

We found by simply standing a Vertical Tumble Stirrer on end using a VP 710C5-3 or VP 710C5-3A we created the world’s first LATERAL VORTEX MICROPLATE TUMBLE STIRRER (USA Patent #7,484,880, European Union Patent #1,736,235 and German Patent #60 2006 026 122.5). Instead of tumbling a stir element in the vertical plane like our Alligator Tumble Stirrer, the Lateral Vortex Tumble Stirrer spins the stir elements by tumbling them laterally against a side wall of the vessel. This spinning motion produces a vortex cone in the liquid and efficiently mixes the contents of the liquid. This vortex cone is similar to the vortex cones produced by conventional horizontal magnetic stirrers however unlike the conventional horizontal stirrers which require a unique drive magnetic field under each vessel, the Vortex Stirrer because of its lateral wall tumbling action only requires one drive magnetic field to stir thousands of vessels. The Vortex Tumble Stirrers work best with round micro wells, or round tubes, vials and bottles. Basically our customers can convert our VP 710 series Tumble Stirrers into Lateral Vortex Stirrers by standing them on end with our accessory stands (VP 710C5-3 or VP 710C5-3A) which hold the stirrer vertical.

The Lateral Vortex Tumble Stirrer causes stir elements of all sizes and shapes to tumble laterally and create a vortex cone inside each well. The Lateral Vortex Tumble Stirrer will stir all types of microplates (24, 48, 96, 384 and even 1536 wells). It will also stir V and U bottom microplates, PCR plates, micro-centrifuge tubes, test tubes, vials and bottles. The only Stir elements that are not compatible with the Lateral Vortex Tumble Stirrer are the Stainless Steel Discs as the magnetic field in these stir elements is oriented through the diameter of the disc. These discs will simply spin in the wells causing little stirring action.

Advantages of the System

• Can stir multiple, vials, tubes, large vessels and microplates simultaneously

• Complete stirring of large numbers of samples

• Uniformity of stirring of wells throughout the microplate

• Can run multiple experiments in parallel

• Get more reactions per gram of starting material

• Will stir even viscous solutions (honey & glycerol)

• No cross contamination – wells do not have to be sealed

• Simple to operate

• Customizable to robotic systems

• Can stir continuously for years without maintenance

• Computer control option is available

Gifs