V&P Scientific’s Hydrophilic coating

Our Hydrophilic coating is a very hard, abrasion resistant and chemical resistant surface for metals and ceramics. It resists all acids except hydrofluoric, all bases, and all polar and non-polar solvents. It exhibits good thermal conductivity from lattice phonon conduction from its strong bonding and because it is comprised of comparatively light atomic species. It also is a high dielectric surface from the lack of conduction of free electrons across a large electronic bandgap. Effective coating on metals for corrosion resistance are nearly transparent and thin, in the range of 750 to 1200 Angstroms. Effective coatings for abrasion resistance are deeper, in the range of 1500-2000 Angstroms, and tend to be more opaque. The maximum service temperature in an oxidizing atmosphere is 1200C, and will offer protection in a reducing or an inert atmosphere to 2010C. The coating is applied in an environmentally benign process, and potentially damaging plasma energy is not utilized. It is a FDA approved material for full-food contact, for surgical instruments, and for surgical implantation. It is can be autoclaved and may be chemically sterilized.

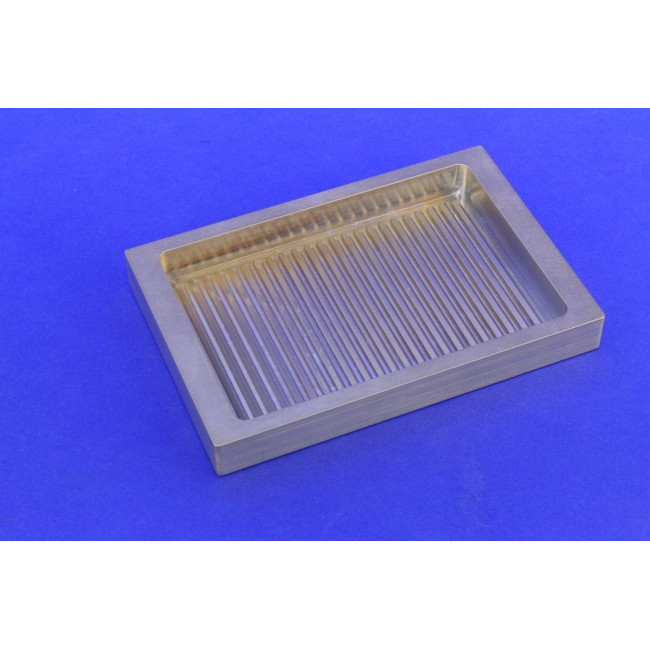

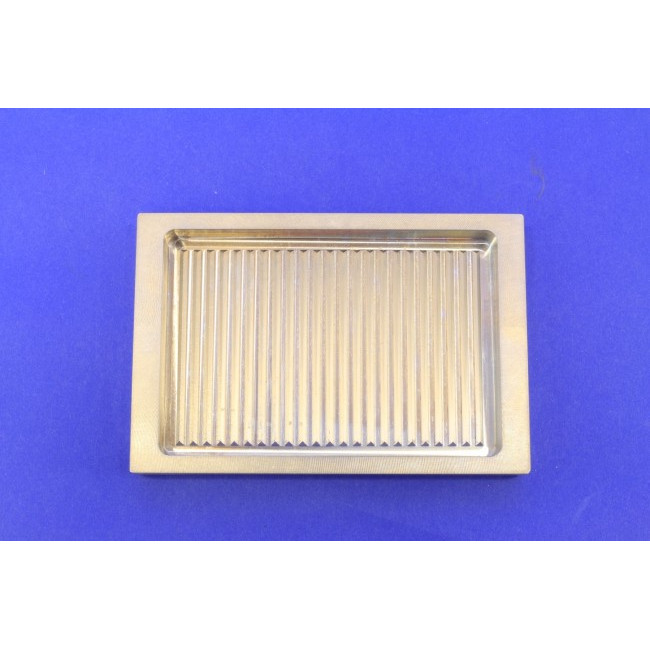

Advantages of Hydrophilic coated reservoirs

The hydrophilic coating on our aluminum reservoirs maximizes the recovery of the reagents used in them. The hydrophilic coating prevents droplet formation and causes the reagent to collect in the dimpled area. We also facilitate this collection of reagent in the dimples by bringing the walls into the dimpled area and then rounding that corner to prevent loss of liquid in the corner. The Polypropylene, Delrin and PTFE reservoirs described above all are hydrophobic and leave droplets of reagents in the flat areas and in the corners and therefore have larger "dead volumes".

Another advantage of the aluminum reservoirs with control wells is that we can make the separating walls thinner with aluminum than with the plastics (Polypropylene, Delrin and PTFE) 0.7 mm thick versus 1.3 mm thick, thus eliminating potential problems with some brands of pipet tips hanging up on the separating walls when they near the bottom of the reservoir.

A third advantage of the hydrophilic coated aluminum reservoirs is that air bubbles are not trapped in the dimples in the bottom. Just pour a little reagent in, swirl and the dimples fill with your liquid and air is not trapped in the dimple. This is not the case with Polypropylene, Delrin and PTFE where the air in the dimples has to be removed (dislodged by pipet tip) or by centrifugation.

Our hydrophilic coating is not affected by 30% H2O2, salt, all acids except hydrofluoric acid, all bases, all polar and non-polar solvents, and potassium ferrocyanide. It also can be autoclaved and chemically sterilized.